By Bryony Collins, Bloomberg New Energy Finance editorial team. This article first appeared on the Bloomberg Terminal and is available to BNEF clients on the web.

General Electric said it is using artificial intelligence to make thermal power plants “more dynamic” and able to quickly respond to changes in the supply-demand balance on the U.S. grid.

With increasing amounts of intermittent wind and solar power coming online, baseload power plants are required to ramp up in a matter of seconds when the wind doesn’t blow or the sun doesn’t shine.

“We need to adapt the thermal fleet to this new world, to allow it to still serve a purpose on the grid and help to incorporate more renewable energy,” said Mary Cauwels, product marketing manager of application performance management at GE Renewable Digital, in an interview with BNEF. AI can be used to “adjust how the power plant equipment runs in real time to help achieve more efficiency, flexibility and capacity”, she explained.

The technology is particularly useful for utilities with mixed fleets of thermal power and renewable generation. GE is working with Invenergy, PSEG Inc and Exelon Corp to help improve the efficiency of their thermal power fleets in the U.S. and “better predict wear and tear on the machines,” said Cauwels.

System operators will be less likely to curtail renewables if they know that thermal power generation can be ramped up quickly at times of supply shortfall, she said. At gas-fired power plants, GE has been able to get an additional 15 megawatts onto the grid in the space of a minute, by using machine intelligence and automation to increase the ramp rate of such assets.

GE is also using AI to predict failures ahead of time at wind and solar plants, and this can bring about significant savings for the customer. Using digital twins – a digital simulation of a real life asset – at wind parks can increase annual energy production by 3 to 5 percent, John LaFleche, senior director of data and analytics at GE Renewable Energy, said in the following interview.

Read the BNEF research note: Can Artificial Intelligence Boost Margins in Energy (web I Terminal) for more detail about how machine learning helps reduce the cost of operations and maintenance and boost revenue at wind farms to oil pipelines.

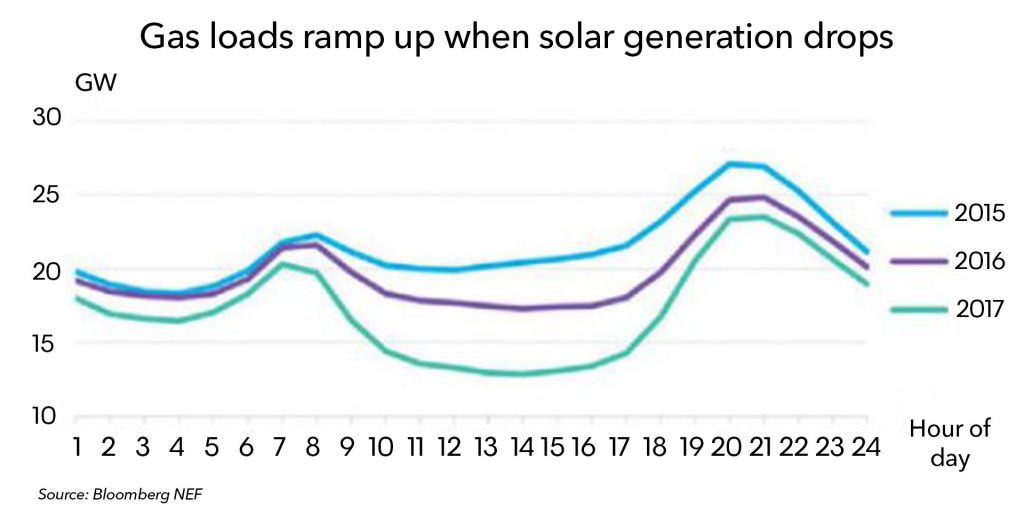

Above graph: The California systems operator’s average net load for the last week of March 2018. The need for gas generation is depressed in the sunlit hours of the day due to the contribution of solar power, and is increased before the sun rises and after it sets. From the BNEF research note: Power Market Design Series 7: California (web I Terminal).

BNEF: How can AI and digital twins increase the value of renewable energy in diversified energy portfolios?

Mary Cauwels: Where a utility or a power generator has a mixed fleet — whether they self-dispatch or bid into a competitive market — the more energy that can be put onto the grid from wind and solar impacts the role of thermal plants.

Many of these plants were originally built as baseload – meaning they are designed to be on all the time at full load. Because we can supply major portions of the day with enough renewable energy to meet demand now, we can turn down the thermal plants and in some cases shut them off completely.

So, for the thermal fleet to be more dynamic, it needs to start more often, respond quickly and turn down or shut down when no longer needed. We’re using machine learning and artificial intelligence to safely push the plant to wider operating modes to combust fuel more efficiently and to better predict wear and tear on the machines.

We can adjust how the power plant equipment runs in real time to help achieve more efficiency, flexibility and capacity within emissions limits, while reducing some of the wear and tear on the machines. So, if for some reason, solar generation drops and we need a gas or coal power plant to immediately respond, machine learning and AI help to determine the best way to ramp up quickly and supply the missing megawatts. And we can also keep maintenance within the planned outage window.

We need to adapt the thermal fleet to this new world, to allow it to still serve a purpose on the grid and help to incorporate more renewable energy. If the system operator is confident that the thermal plants have the renewables’ back, then they’ll be less likely to curtail the renewables. Because they know that if for any reason the wind stops blowing, they can quickly ramp up another asset and there’ll be no issues in balancing supply and demand.

Q: Where have you been applying that?

Cauwels: We’ve been working with Invenergy on their thermal fleet, in addition to their wind and solar fleet. And with PSEG and Exelon.

Q: Do you have an example of where you’ve improved responsiveness of a thermal power plant?

Cauwels: We’ve been able to help certain classes of gas-fired power plants to improve ramp rates plus or minus 50 megawatts per minute. That means getting an additional 15 megawatts onto the grid in a minute.

And they also can handle frequency of plus or minus 2 hertz per second, which is really responsive.

Q: How is GE implementing AI in solar?

Madhuri Adettiwar (chief digital officer of digital solar products): We are using AI in three different ways – digital twins, comparative analytics and predictive analytics. The foundation is GE Digital’s Predix platform, and we’ve built a solar product on top of that.

This product is primarily for monitoring the health and status of equipment at a solar power plant. We are able to predict failures in inverters and the effect of those failures on solar power production.

It brings value to the customer in two ways. One is the O&M [operations and maintenance] phase – through analytics and machine learning we are able to predict failures ahead of time so that maintenance work can be scheduled accordingly.

We’ve been able to predict failures in GE inverters as far as 90 days in advance. We can go to the sub-component levels within the inverters, and point out which electrical components inside a component are going to fail and the maintenance work needed. With this type of predictive analytics, there are substantial O&M savings for the customer.

The other value-add is performance loss. We are able to tell them what the expected performance should be based on current operating conditions, and compare that with the actual performance.

And then we break down the difference between expected and actual performance to identify – what’s causing the performance loss — such as inverter failure, string outages or soiling – as well as what percentage of total loss is caused by each factor.

Q: Who are your customers?

Adettiwar: We have three customer segments we are focusing on – IPPs [independent power producers], O&M providers and equity holders. We have signed digital deals with several IPPs and O&M providers.

Q: What are the average savings possible from reducing performance loss?

Mona Hall (product marketing lead of digital solar): At one customer’s 20-megawatt solar plant in North America, we’re expecting benefits of improved performance and reduced O&M cost to translate into about $200,000 in value per year.

Q: What about wind energy?

John LaFleche (senior director of data and analytics): We have a huge installed base of wind energy where we’ve been building digital twins around performance and major components for many years.

We constantly monitor all turbine output relative to wind speed and compare that to what the wind turbine ought to be doing. If we’re not producing the expected output, we have digital twins that tell us the root cause of the under-performance.

We also compare turbines with others in the same wind park and compare against the expected characteristics of different manufacturers. We monitor sensors on a turbine to check for any outliers and find any potential damage or maintenance required.

And then we look at major components such as a gearbox or blade with the digital twin. Effectively, we’re building a digital twin that says, is this component performing the way that it should based on the signals that we are receiving? We do diagnostics on unhealthy components, and run prognostics on the remaining lifespan of particular components.

Q: Where have you been implementing this?

LaFleche: We’ve implemented this on our own service fleet for many years, and now with pilot customers – a number of large European and U.S.-based IPPs and utilities. We have a 60-gigawatt installed base of wind turbines, which represents a significant presence in this segment.

Q: How have you demonstrated improved production at wind plants for external customers so far?

LaFleche: Typically, with digital capabilities we see availability increase by about 1 percent. We can drive annual energy production up 3-5 percent, and reduce costs for maintenance by around 2 percent, year-over-year.

We have more than 100 models with comparative analytics in place.

Read about the opportunities for machine learning in electricity systems in the BNEF research note: Machine Learning and Electricity Systems (web I Terminal).