This article was written by Nelson Nsitem, Senior Associate, Energy Storage, and Yayoi Sekine, Head of Energy Storage, BloombergNEF. It appeared first on the Bloomberg Terminal.

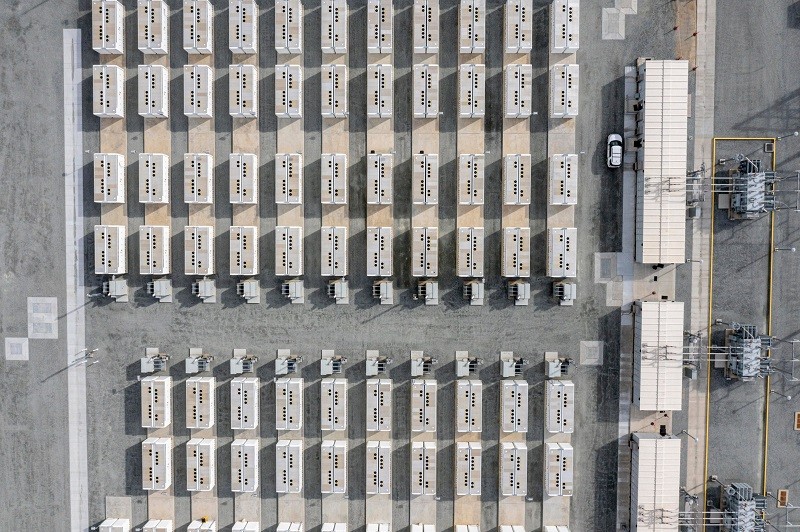

The global energy storage market is poised to hit new heights yet again in 2025. Despite policy changes and uncertainty in the world’s two largest markets, the US and China, the sector continues to grow as developers push forward with larger and larger utility-scale projects. Since 2024, gigawatt-hour projects have been commissioned or started construction in not only the US and China, but also Saudi Arabia, South Africa, Australia, Netherlands, Chile, Canada and the UK.

BloombergNEF expects additions to grow 35% this year, setting a record for annual additions, at 94 gigawatts (247 gigawatt-hours), excluding pumped hydro. The bumper year will be followed by a compound annual growth rate of 14.7% through to 2035, with annual additions reaching 220 gigawatts/972 gigawatt-hours that year, based on BNEF’s latest outlook.

Market movements

Mainland China accounts for most of the global energy storage demand, driven in the near term by regional requirements for new utility-scale wind and solar projects to include energy storage capacity. However, the Chinese market is entering an era of change. New policy introduced in February 2025 requires wind and solar payment mechanisms to move toward more market-based structures, where 100% of wind and solar generation is to be traded in the wholesale market with local governments left to define their own implementation details by the end of the year.

For energy storage, the new Chinese policy emphasized the need to remove energy storage as a prerequisite for renewable energy project grid connection, a requirement that has been a major driver for battery build. Nonetheless, BNEF still expects strong demand for batteries, as the policy doesn’t explicitly require mandates to stop. Since the policy announcement, some provinces across China have continued to announce mandates stipulating that new solar and wind projects must be paired with batteries. Details on local implementation of new policy will determine how much the shift in deployment drivers from mandates to economics will further affect energy storage build.

In the US, BNEF’s expectations cooled as higher tariffs on imports are driving up battery prices and slowing build. The US energy storage market is feeling the pain from higher import tariffs on goods from China, Canada, and Mexico, with President Donald Trump raising import tariffs since he returned to the White House this year.

The tariff timeline is such that Trump increased base tariffs by as much as 145% on imports from China on April 10. BNEF’s base-case analysis looks at a blanket 54% import tariffs, which immediately inflate four-hour turnkey system costs by 30% in 2025 (to $266 per kilowatt-hour) compared to without the raised tariff. BNEF’s higher tariff scenario, at 145%, leads to between 51% and 74% lower build annually between 2025 and 2027 relative to BNEF’s base-case scenario.

With higher-than-expected costs, supply contracts are being renegotiated, projects are being delayed and canceled. These tariffs also increase production costs of US-made batteries as the US still needs to import battery materials, including graphite, from China for domestic battery production.

Gigawatt-scale projects

Globally, energy storage project development is increasingly driven by the utility-scale segment, with mandates and targeted auctions driving gigawatt-hour projects in markets like China, Saudi Arabia, South Africa, Australia and Chile.

Across the region of Europe, the Middle East and Africa, the utility-scale segment is scaling quicker than expected, and will overtake the residential sector to become the largest in the region from 2026, given a sharp ramp-up in targeted support programs and utility procurement.

The residential segment has been more mixed, cooling slightly in Europe but expanding markets such as California due to policy changes in 2024. Commercial battery deployments overtake residential build by 2030in BNEF’s latest outlook, thanks to updated assumptions on attachment rates, which refer to the percentage of solar installations that are paired with a battery.

Technology locked in

Lithium iron phosphate (LFP) remains the prevalent lithium-ion battery chemistry in the stationary energy storage market. Chinese battery makers, which specialize in LFP production, continue to benefit from the growth of the domestic market and aggressive overseas expansion.

Most major battery makers, such as Contemporary Amperex Technology Co. Ltd. (CATL), BYD, EVE Energy, CALB and Hithium, develop products specifically for the energy storage market, driving a continued deviation from the electric-vehicle chemistry mix, which features a larger proportion of nickel-based lithium-ion battery chemistries. Compared to LFP, nickel-based chemistries such as nickel manganese cobalt oxide (NMC) and nickel cobalt aluminum oxide (NCA) are more energy dense, allowing automakers to offer lighter and longer-range EVs.

In Japan and South Korea, where battery manufacturers have historically specialized in nickel-based chemistries, BNEF assumes a share of manufacturing will meet energy storage demand domestically and can continue to supply diminishing NMC demand overseas out to 2035.

In the US, BNEF also assumes NMC may feature in utility-scale projects until at least 2027. Even though the shift toward LFP is clear, 2024 saw large shipments of NMC batteries for energy storage. The impact of very high tariffs on imports from China, where the vast majority of LFP batteries is manufactured, will reduce demand for energy storage in general in the US, but make any NMC available from outside of China more viable.

Expectations for sodium-ion batteries among manufacturers have cooled as LFP prices continue their downward trend, leading to BNEF’s lowered expectations for sodium-ion technology to scale.