By Brenna Casey, Associate, Sustainable Materials at BloombergNEF

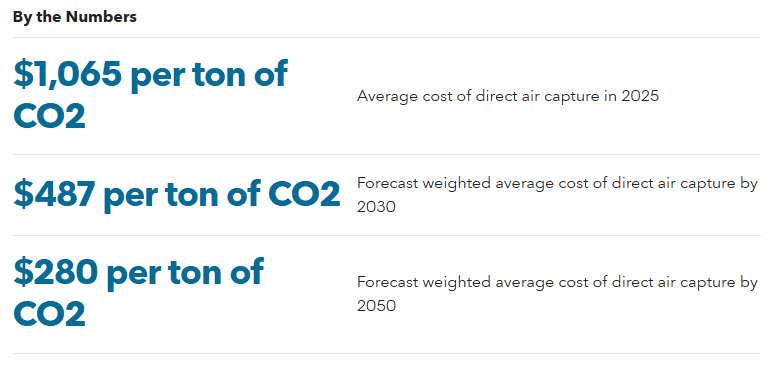

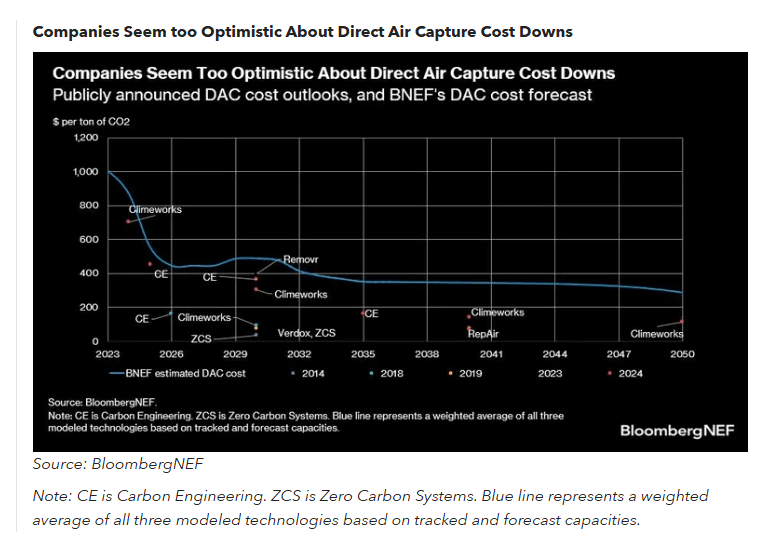

Direct air capture removal credits are prohibitively expensive for all but a select few large companies with ambitious sustainability goals. To make this solution more accessible and accelerate demand, costs must fall. Modular plants, optimized processes and improved efficiency of the CO2 capture system can all facilitate cost reductions, but the inherent features of each technological configuration will influence how quickly costs can fall.

- Liquid absorption exhibits the lowest first-of-a-kind cost for any direct air capture (DAC) system, thanks to its ability to adapt and use several commercially available components, as well as its potential to achieve a higher scale of operations. But this limits the opportunities for learning by doing, and this technology may not be the least-cost option in the long term.

- Companies such as Climeworks, Removr and RepAir are developing and deploying solid adsorption-based DAC and electrochemical DAC solutions as alternative technologies. These rely on modular designs which are ubiquitous with faster capex reductions, as seen with solar or lithium-ion batteries. Integrated designs, on the other hand, tend to preclude higher learning rates, as seen in the nuclear industry.

- Capital costs are generally expected to be more malleable than operating expenses during the early stages of technological development as companies deploy larger plants and establish more-efficient equipment supply chains. Technologies with a greater share of capex in the overall cost of capture thus have greater potential to reduce nth-of-a-kind costs. Opex reduction is relatively contingent on thermodynamics, and operations and maintenance costs.

- A DAC plant should run at high utilization rates to amortize the steep capital costs. If a DAC plant is reliant on renewable energy, where intermittency results in low capacity factors, then the price of electricity must be low enough to compensate for the system’s low utilization rate.

Allen Abraham, Head of Sustainable Materials at BloombergNEF contributed to this article.

BloombergNEF clients can access the full analysis here.