REPORT

BloombergNEF Announces 12 Climate Innovators as Winners of its 2025 Pioneers Award

BNEF’s annual Pioneers award recognizes game-changing technologies or innovations with the potential to accelerate the transition toward a net-zero economy across three key climate challenges.

BloombergNEF (BNEF) today announced the winners of its 2025 Pioneers award, recognizing 12 early-stage companies working to introduce technologies and products that will accelerate global decarbonization and help economies adapt to climate change. This year’s winners include companies improving the resilience of food supply chains, developing novel routes for electrifying industrial heat, and pushing energy storage systems into new markets – among many others.

Since its inception over a decade ago, the BNEF Pioneers program has witnessed significant advancements in the development and implementation of technologies and solutions aimed at decarbonizing the global economy. While BNEF analysis estimates that global emissions may have peaked in 2024, there are still many urgent obstacles to overcome for the world to reach net-zero emissions. Further, climate change is already impacting, and will continue to impact, the world. For the first time, the Pioneers program sought innovations helping to manage the impacts of climate change.

The BNEF Pioneers award aims to highlight companies that are making significant strides in sectors or areas that still face challenges. This year, BNEF invited nominations from ventures specifically targeting three climate-tech innovation areas:

- Making light industry more sustainable

- Innovations in energy storage

- Boosting climate adaptation capabilities

The competition received over 700 applications from 35 markets. These were evaluated by the BNEF analyst team against three criteria: the potential impact on greenhouse gas emissions and the planet, the degree of technology innovation and originality, and the likelihood of adoption and potential scalability.

The winners of the 2025 BNEF Pioneers are:

Challenge 1: Making light industry more sustainable

- AtmosZero is electrifying steam production globally with its Boiler 2.0 technology and generating steam that is cost-effective, scalable and deployable today.

- Circ is a textile-to-textile recycling innovator with the technology to recycle and recover polycotton blends, transforming waste into new, circular raw materials for the industry.

- Everdye is developing bio-based dyeing solutions to decarbonize the textile industry.

- Rondo is helping the world’s most difficult-to-decarbonize industries rapidly lower their energy costs and carbon emissions.

Having made many of the easier early gains in sectors such as electricity generation and transportation, the energy transition needs to find pathways to reduce greenhouse gas emissions in hard-to-abate sectors. Today, one-third of industrial emissions are derived from ‘light’ industries such as pulp and paper, food and beverage production, textiles, and glass and ceramics.

Two of our winners in this challenge offer technical pathways to electrify low-temperature industrial heat, displacing the incumbent fossil fuel boilers. Rondo’s thermal battery can store cheap intermittent electricity quickly and then discharge the energy as steam to serve industrial heat demand throughout the day. By contrast, AtmosZero’s industrial air-source heat pump is not site specific, allowing them to be deployed more rapidly than existing products.

By contrast, Circ and Everdye both address the environmental impact of the textiles industry, which currently accounts for around 8% of global greenhouse gas emissions. Circ’s textile recycling process keeps used textiles out of landfill and displaces fossil fuel feedstocks in virgin fiber production, whereas Everdye’s dyeing technology eliminates the need for heat during dyeing.

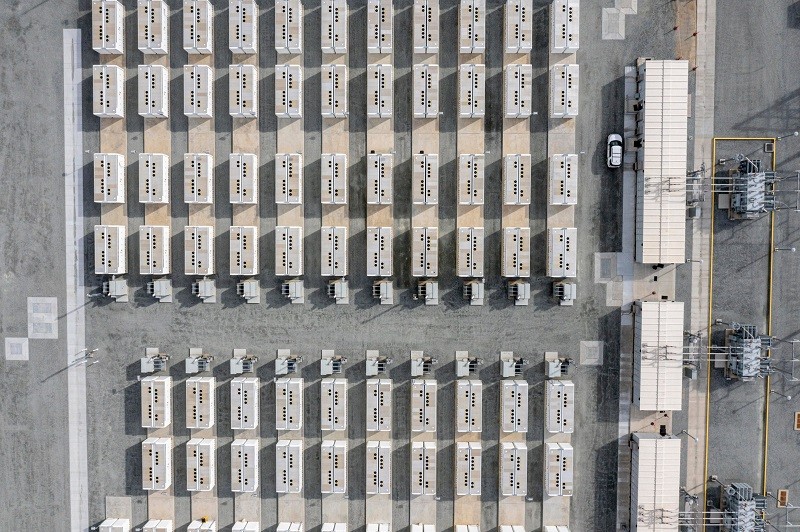

Challenge 2: Innovations in energy storage

- Hytzer is transforming high-performance and high-safety solid-state battery (SSB) technologies into commercial products.

- Instagrid is redefining portable power, offering innovative, sustainable solutions that meet demanding off-grid energy needs.

These BNEF Pioneers are both driving innovation in the already mature sector of energy storage. Instagrid’s ONE and GO products utilize lithium battery technology to displace highly polluting diesel generators in a wide range of off-grid applications, such as construction sites or film sets. Hytzer, meanwhile, is a leader in the production of solid-state batteries, which promise improvements in cost, safety and energy density over incumbent chemistries.

Challenge 3: Boosting climate adaptation capabilities

- AiDASH is making critical infrastructure industries climate-resilient and secure with a satellite-first AI platform.

- Beewise is helping make pollination services more resilient. Its AI-operated robotic beehives protect bees from extreme weather, disease and chemicals.

- InnerPlant is engineering crops that emit optical signals when stressed, providing farmers with early and actionable data that helps improve yields and reduce chemical use.

Whether the world is brought onto a two-degree emissions pathway or not, climate change has already had, and will continue to have, significant impacts. Two of the companies selected are helping to improve food security, with InnerPlant’s genetically modified soybeans allowing for earlier diagnosis of, and more precise intervention against, fungal infections. Beewise is focused on a different dimension of food security, improving the resilience of pollination services by protecting bee colonies. By contrast, AiDASH is improving the reliability of critical infrastructure such as power grids in the face of increased physical climate risk.

Wildcards:

- Binding Solutions Limited is making cold agglomerated pellets to significantly cut CO2 emissions, lower capital requirements and reduce process complexity in iron making, enabling green steel production at scale.

- Coolbrook is decarbonizing major industrial sectors with innovative rotating technology that replaces the burning of fossil fuels.

- Reclinker is making low-carbon, recycled cement, processing it through steel electric arc furnaces.

The Wildcard winners are organizations working outside of this year’s three core subject areas. These all have a focus on reducing the pollution associated with industrial processes. Two companies are aiding electrification, with Coolbrook manufacturing rotating heaters capable of producing 1,700C electrically powered heat. A modified version of the technology can also be used for naphtha cracking. Reclinker, meanwhile, has developed a new process for making recycled cement, using steel electric arc furnaces, simultaneously reducing steel recycling emissions.

Binding Solutions Limited offers a process to upgrade iron fines into pellets, a feedstock for steelmaking. This process does not require thermal energy, which cuts out a significant cause of fossil fuel usage.