By Michael Liebreich

Senior Contributor

BloombergNEF

In January this year, BloombergNEF announced that investment in the clean energy transition had broken through the $1 trillion mark in 2022, for the first time matching the total investment in fossil fuels. Just under 90% of the funds went to just two sectors: renewable energy and electric vehicles, which each attracted nearly half a trillion dollars. This was good news for the climate, but does beg the question, which will be the next clean energy sector to attract half a trillion dollars per year?

Background

It was a matter of considerable satisfaction to see renewables and electric vehicles attract nearly half a trillion dollars each. In 2004, when I founded New Energy Finance, investment in renewable energy was just $32 billion. In 2010, when I named electric transportation as a mega-trend at the first BloombergNEF Summit, investment in electric vehicles was still less than $2 billion.

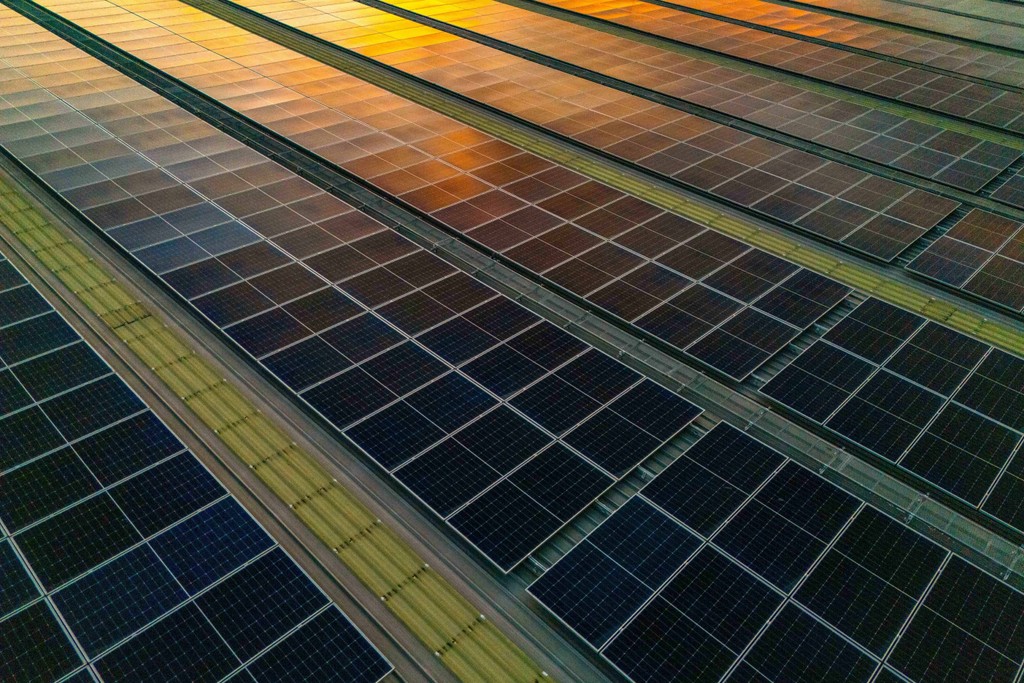

Both of these sectors are set to power on, as described in my piece in September last year on the Great Clean Energy Acceleration. The International Energy Agency is expecting as much renewable capacity to be built in the next five years as in the past two decades. And, after the recent change of leadership at Toyota, all the major car companies are focused almost exclusively on electrification (give or take a few hydrogen concept car projects).

Wind and solar have grown from nearly nothing two decades ago to account for 15% of global electricity, and the EU, UK and the US have all pledged to eliminate emissions from electricity entirely by 2035. However, electricity only meets just over 20% of global end-use energy demand. Add in land transportation, on track to be substantially electrified and decarbonized by 2050, and you still only get to 40% of energy-related emissions.

Hence the question: which clean energy sector will be next to take a big bite out of the remaining 60% of global demand, and become the next half-trillion-dollar investment opportunity?

Hydrogen’s loss is electricity’s gain

Goldman Sachs is backing hydrogen: they have predicted that it will absorb investment of EUR 10 trillion ($11 trillion) by 2050, an average of $400 billion per year. McKinsey and Company, in a report produced for the Hydrogen Council agree. The Energy Transitions Commission is even more bullish, estimating investment of $15 trillion in hydrogen over the next 27 years, an average of $890 billion annually.

These estimates are predicated on the global demand for hydrogen growing from 94 million tonnes per year to 660-800 million by 2050. In my view, based on my work on the demand side (summarized in the Hydrogen Ladder) and on the devastating economics of transporting hydrogen other than by pipeline described in my last BloombergNEF blog, the figure is unlikely to exceed 250 million tonnes.

So, while trillions of dollars will indeed be invested in hydrogen in the coming decades, the annual amounts will be around a third of the half-trillion-dollar scale predicted by the sector’s cheerleaders.

If hydrogen is going to fall short of expectations, the corollary is that electrification needs to over-deliver. It may not be a case of “electrify everything”, but it is definitely “electrify everything you reasonably can.” And this means the next sector to take off in a big way is going to be the electrification of heat.

Let’s get to work – some thermodynamics

Before we dive in, there is something I wish more policymakers, economists and investors understood: energy has quality, as well as quantity.

A joule of electricity is worth much more than a joule of low-grade heat because a joule of electricity can do “work” – lifting a weight, powering a motor and so on – while low-grade heat cannot. A joule of electricity is also worth more than a joule of chemical energy, because while a fuel can do work, you first have to put it through a chemical process, during which there are inevitably losses.

Scientists call the ability to do work exergy (confusingly, also measured in joules). Efficiency does not mean just making the most of energy, it also means making the most of exergy.

Let me start with a simple illustration: say you have a house, which you warm with a resistive electric heater; your neighbor has an identical house, except it also has an elevator. All of the energy used by your neighbor’s elevator eventually ends up as heat – in its motor and braking as it lowers its loads – so she doesn’t have to run her electric heater as hard. Both of your houses are warm, and you have the same electricity bill. She, however, enjoys the additional benefit of an elevator, because she is extracting work from her electricity before it ends up as heat. She is making better use of exergy.

Now let’s apply the same principle, not to provide an additional benefit, but to reduce energy consumption. Instead of an elevator, suppose your neighbor’s house has a heat pump. Again, the energy content of all the electricity she uses ends up as heat, but this time, along the way, it is pumping a working fluid around a circuit in such a way that it moves additional heat into her house from outdoors. Now she enjoys the same comfort as you, but with a lower electricity bill. Again, she is making better use of exergy.

As we redesign the interplay between heat, electricity and fuels in the future net-zero energy system, we must be efficient in our use of exergy as well as energy. This means not using electricity to make fuels (unless you have to), not using fuels to do work that electricity can do, and not using flames at 2,000 centigrade to provide low-temperature heat.

If you forget everything else here, please remember this: all joules are equal, but some joules are more equal than others.

Heat pumps for the win

We are constantly told that there are no silver bullets in the fight against emissions; the closest thing we have is a heat pump.

So elegant are heat pumps that if you were to take the gas currently being used to heat your home and burn it in a power station, you could generate enough electricity to heat three homes. This is the main reason why all independent studies, 37 of them at the latest count, find that hydrogen has little or no role to play in space heating: even if you were given hydrogen for free – something the Inflation Reduction Act (IRA) in the US could well do for the next decade or so – it would still make no economic sense to use it to heat one home when you could heat three using heat pumps.

Heat pumps not only deliver energy efficiency and decarbonization, they also hold the key to eliminating energy-related production of nitrous oxides in the home and in residential neighborhoods. A recent paper estimated that gas furnaces and open-flame cooking are responsible for one in eight cases of childhood asthma in the US; the figure in the UK is probably twice that, because of the enduring popularity of cooking on gas.

Over the past few years, the heat pump market has finally begun to take off. The IEA recently released figures showing that global sales grew 11% in 2022, and heat pumps now meet around 10% of all space heating demand worldwide.

The European Heat Pump Association reports that installations in Europe have tripled to three million over the six years to 2022, a 20% compound annual growth rate, accelerating to 36% over the past two years. Poland was the star, with growth of 120% to 200,000 installations in 2022, while the UK brought up the rear.

In the US, 4.3 million heat pumps were installed last year, up from 2.3 million in 2015 and, for the first time, heat pumps outsold furnaces. The trend is set to continue, with $4.5 billion set aside under the IRA to help consumers ditch gas appliances and go electric.

Technological innovation too is picking up. Hydrofluorocarbon refrigerants, which have high global warming potentials if they leak, are being replaced with more benign ‘natural’ refrigerants like propane. Vaillant, Bosch and other manufacturers have launched models that deliver heat efficiently at up to 75 centigrade, removing one of the key excuses for not replacing boilers in older, leakier properties.

One reason Europe found it so hard to get off Russian gas last winter was because many district heating systems are fed by gas-powered combined heat and power plants (CHP). Megawatt-scale heat pumps from startups like Star Energy in Scotland and engineering majors like Siemens can upgrade heat from local rivers to 70 centigrade and more to feed these systems, as can a new generation of closed-loop deep geothermal players.

District heating, however, does not need to be at these temperatures. One of the most promising approaches is shared-loop ground-source heating, where UK startup Kensa is the world leader. Water circulates at temperatures as low as 10 centigrade, and a small heat pump in each individual home upgrades the temperature to meet demand for heating and hot water. This opens up entire neighborhoods and tower blocks to heating via ground-source or low-grade, locally-available waste heat. Unlike high-temperature district heating, there is limited thermal loss from pipes; unlike air-source heat pumps, there is no loss of efficiency when the weather is cold.

Companies like Sunamp, Tepeo and Mixergy are offering domestic thermal storage solutions, helping heat pump owners ride through demand peaks and take advantage of cheaper time-of-day tariffs. Add in intelligent home energy management systems and the ability of heat pumps to provide cooling during summer, and it is clear we are at the start of a domestic heating revolution – simultaneously saving energy, switching its source to clean electricity and providing superior health and comfort.

Industrial heat is going electric

Over 20% of global final energy consumption is in industry. One of the most eye-opening papers I have read in the past decade was this one, dating to 2019, by Potsdam Institute researcher Silvia Madeddu and colleagues. It found that – if you exclude the use of natural gas as a feedstock or reducing agent – an astonishing 78% of Europe’s industrial energy demand could be electrified using technologies described as “fully developed and established in industry”. When they added technologies that were at lower stages of development at the time of the research, the figure increased to 99%.

According to the International Renewable Energy Agency, nearly half of industrial heat demand is at temperatures below 200 centigrade, used in equipment like tunnel ovens, dryers, stills and steam boilers. There is no reason why all of it could not be delivered by heat pumps, running on clean electricity, with coefficients of performance (COPs) of two or more – in other words halving heat demand, meeting it with clean electricity, and saving between half and two thirds of the costs of a conventional gas-fired steam boiler.

Companies like Heaten, ECOP and SPH offer heat pumps that can deliver heat at up to 165 centigrade with a COP of well over two. Fuji sells a heat pump that produces steam at 120 centigrade from 80 centigrade waste heat with a COP of 3.5. Kobe Steel offers a heat pump that produces high pressure steam at 165 centigrade with a COP of 2.5. Technologies under development are aiming to deliver heat at up to 250 centigrade.

For medium and higher temperature heat (over 200 and over 400 centigrade respectively), which together account for the remaining 55% of industrial heat demand, we are often told that only gas combustion can work. This is simply not true. There is a whole range of electrical technologies – infrared, microwave and radio wave, induction, resistance, electric arc and plasma – that can deliver temperatures up to 20,000 centigrade.

The metals, glass and ceramics industries are waking up to the scope of the opportunity, with innumerable electrification pilots and increasing numbers of commercial projects.

Make friends with co-benefits

The benefits of switching industry to electrical heating go far beyond carbon intensity.

Almost all industrial processes could, once electrified, be operated at least in part in load-following mode – ramped up when solar and wind power is plentiful, and ramped down or switched off when it is not, supporting the grid and earning extra revenues. Rio Tinto’s Kitimat aluminum smelter in Canada and Hydro in Norway generate “considerable revenue” by supplying demand-side response services to their respective grids, according to a report by the Institute for Energy Economics and Financial Analysis. New Zealand startup EnPot, whose technology is used by 120 smelting pots at TRIMET in Essen, estimates that power demand from aluminium smelting can be flexed up and down by 30%, providing grid firming services at less than a fifth of the cost of pumped hydro.

Even when industrial processes cannot themselves be run in batches or flexed in response to power price signals, they may still be able to run on variable power, courtesy of thermal storage. Startups such as Rondo, Energy Nest and Alumina Energy are working on thermal storage at temperatures up to 1,600 centigrade, high enough for use in cement clinker production, as Rondo is demonstrating with Titan Cement Group.

Electrification of cement kilns – being piloted for instance by Mexico’s Cemex in partnership with ABB-backed Coolbrook – reduce CO2 emissions by around half, leaving only those produced chemically during calcination. The resulting process emissions are no longer mixed with combustion exhaust, so instead of containing just 25% CO2, the flue gases are nearly pure, enabling them to be sequestered without a costly CO2 separation stage.

Electrification also opens up efficiency opportunities within the industrial equipment itself. Heating with gas produces a stream of hot exhaust gases, as well as radiative heating – which in certain processes is an advantage, but more often is not. Electrical heating can be delivered in a highly targeted way and with no stream of hot exhaust gases. Schneider Electric estimates that switching from fossil fuel to electric melting at the start of the glass-making process can deliver a 35% efficiency boost.

Additive manufacturing – all of which will be electrically powered – will unlock dramatic efficiency improvements through elimination of waste (no more grinding, milling and re-melting of waste swarf), but it will also directly reduce demand for high-temperature heat. In a 3D powder bed fusion printer, lasers melt a little metal powder at each pass, removing the need to heat an array of furnaces, crucibles, molds and so on during a casting process.

We still aren’t done with the benefits of electrification. When speciality steel company Ovako electrified all 150 of its heat treatment furnaces, it found that one of the biggest paybacks was from reduced maintenance costs. Safety improves because fuel you are not using can’t leak or ignite. Nor can greenhouse gases – whether methane, hydrogen or CO2 – escape from a system which is electric from start to finish. Working environments will improve, with less noise, heat and noxious fumes. Whole regions will see reductions in air pollution.

The main barrier to the electrification of heat lies in the relative cost of electricity and natural gas. This is driven in part by unpriced externalities and taxation systems that effectively subsidize fossil fuels, but also by commodity prices.

In the US, since the advent of fracking, the price of natural gas has averaged around $3 per million BTU. Delivering heat electrically at that price would mean paying no more than $10/MWh; doing the same via hydrogen would require a price of just 34 US cents/kg. In Europe and Asia, if you set aside the price spike caused by Russia’s invasion of Ukraine, LNG should cost no more than $7/MMBtu. To match that price electrically, you need to buy clean power at $24/MWh; to do the same using hydrogen would imply a price of 80 cents/kg. Of course, this excludes distribution costs, but you get the point.

What this means is that decarbonizing heat will require some combination of transitioning to much more efficient technologies – as described above – along with carbon pricing and changes to taxation, to shift the cost of the net-zero transition away from increasingly clean electricity, and on to carbon-intensive fuels (as the UK has already announced it will do).

Also of great significance will be reductions in the cost of equipment. Over time, we should expect the experience curve to do for electric industrial equipment what it has done for wind turbines, solar panels and EV batteries. Manufacturers will launch more and more models, knowledge will accumulate, gas engineers will retire and be replaced with electrical engineers and electrochemists, material science and digitization will progress, and supply chains will develop.

Just as electric cars started as costly luxuries but are now generally cheaper to run than internal combustion cars, electrically-powered heating and industrial processes will end up cheaper and better than their gas-powered equivalents.

Heat stress or heat stroke?

The electrification of heat – domestic, commercial and industrial – will require enormous investment in our electrical grid.

Winter heating loads in northern climes can exceed five times current peak electrical demand, and we are told they can never be delivered electrically. However, modern, high-efficiency heat pumps (along with continued progress on insulation) will reduce that figure to parity. Of course, even doubling the capacity of the power grid between now and 2050 presents a huge challenge, but it is feasible from an engineering and economic perspective. It is worth noting in this context that UK domestic power demand was 37% higher than today as recently as 2005.

In its Net Zero Scenario, BloombergNEF estimates that $21 trillion will have to be invested in the electrical grid between now and 2050. Transmission is another sector just itching to get to the half-trillion-dollar annual investment mark, but that is a topic for another day.

Another argument against the electrification of heat is that we need to keep our lights on, our homes and offices warm, our transport working and our factories running even when there’s no wind or sun for extended periods. This is where long-duration storage of hydrogen or one of its derivatives may come in. Again, the engineering is feasible and the economics are affordable, according to modelling by Professor Tom Brown of the Technical University Berlin, and an upcoming paper on behalf of the Royal Society by Professor Sir Chris Llewellyn-Smith of Oxford University.

The important thing to note is that, even if we end up using stored hydrogen to tide us over times of low wind and solar, this does not mean distributing it to homes and main streets. It will be far cheaper and safer to store it centrally, generate power centrally, and distribute that via the grid to meet transport and heating demand.

Finally, Madeddu’s conclusion about the feasibility of electrifying practically all industrial heat does not necessarily translate to China and the developing world, which use far more energy to make primary steel. Unlike the electric arc furnaces used to recycle scrap steel, this is among the hardest processes to electrify directly – although both Bill Gates-backed Boston Metals and Australia’s Fortescue Future Industries are reporting good progress in the direct electric reduction of iron ore.

Despite these caveats, the benefits of electrification are so colossal, and the challenge of making and transporting enough clean hydrogen to decarbonize industry so extraordinary, that the eventual electrification of practically all industrial heat seems inevitable.

Count the cash

Let’s get back to my original question: how quickly might the electric heating market reach the half-trillion-dollar mark?

Of the $1.1 trillion BloombergNEF reported being invested in the net-zero transition in 2022, electric heating accounted for $64 billion (5.8%), with three-year compound growth of 14%. Maintain that rate, and the sector would hit the half-trillion-dollar investment mark by 2037.

This, however, would underestimate the size of the eventual opportunity. First of all, last year’s BloombergNEF figure included only investment in heat pumps and heating equipment itself, plus a bit of venture activity. The figures for renewable energy, by contrast, included far more than just wind turbines and solar panels, while the electric transportation figures included whole vehicles, not just electric drive trains. Investment opportunities in the electrification of heat go far beyond just equipment, into software, balance of plant, construction, services and so on.

Secondly, the heating sector sits alongside the market for HVAC and cooling. Globally, around $120 billion is invested in air conditioning each year, which increasingly looks like climate-related investment: in the global south, cooling is becoming more essential as the climate warms; in the north, heating and cooling are converging, as we have seen. Then there is domestic refrigeration, an $80 billion industry, and industrial refrigeration, at around $50 billion.

Add these and you have a market for electric heat and cooling that is already attracting annual investment volumes of over $300 billion. Improving living standards, the drive for net-zero and the need for energy efficiency mean that we will see long-term growth across the board. Assume electrical heating maintains its current 14% growth rate while the rest of HVAC and refrigeration grows at 5%, and the combined opportunity will reach the half-trillion-dollar mark as soon as 2030.

So, there you have it: within a decade the electrification of industrial and space heating, intertwined with the cooling and refrigeration sectors and deeply integrated into the electrical grid and power markets, will emerge as the next half-trillion-dollar clean energy investment opportunity.

At that point, I would expect the total annual investment in the net-zero transition to have reached around $2.5 trillion. As the saying goes: “half a trillion here, half a trillion there, and pretty soon you’re talking real money.”

Selah!